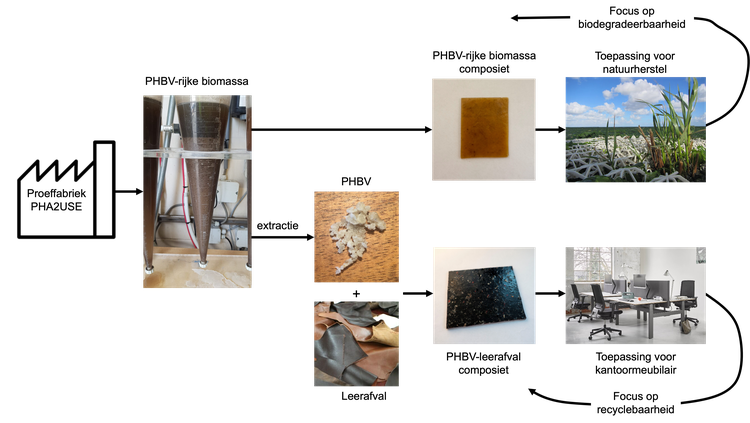

In this project, we develop biobased and waste-based alternatives to plastic so as to support the transition to a more circular and biobased economy. We use PHBV, a biopolymer derived from organic waste, as a base material and add waste from the leather industry and other organic waste streams to develop two new bio-composites. We use the distinct characteristics of these two composites to develop prototypes of two products that serve the furniture industry and nature restoration respectively.

PHBV

In the transition to a circular economy, we aim to maximize the reuse of plastics, whilst minimizing the impact of their primary use. The latter can be done by using biobased resources, made from biopolymers rather than fossil-based resources. PHBV is one such biopolymer, and its characteristics resemble those of polypropylene. In the Netherlands, we use about 500 kilotonnes of polypropylene for plastic products each year – PHBV presents itself a great opportunity for a circular plastics industry.

Overview

PHBV is extracted from wastewater slip and hence, contrary to many other biopolymers, does not compete with any food crops. Using one kilo of PHBV as a replacement for polypropylene saves at least 4 kilos of CO2 equivalent, making its production carbon neutral, or even carbon negative.

In many respects, PHBV can replace fossil-based polypropylene. As an added benefit, this material has a lower melting temperature resulting in less energy use for production, better recyclability, and better compatibility with other natural resources, like fibers. Furthermore, it biodegrades in a natural environment and does not require industrial compositing circumstances.

“In this project close collaboration between biobased feedstock, material and product development take place to create fully sustainable alternatives for a circular society.”

Mariet Sauerwein

Former Research Fellow at AMS Institute

Material and Market

Paques Biomaterials is currently producing PHBV on a pilot scale. The goal of PRO-PHBV is to produce two PHBV-based bio-composite materials and to develop applications from these materials.

- With Bureau Waardenburg, we will develop a composite material by directly pressing the PHBV-rich biomass and omitting the PHBV extraction step. We aim to develop a nature restoration structure from the pressed PHBV-rich biomass.

- With Material Sense LAB and Ahrend, we aim for a leather waste -PHBV composite, which can be used to produce an armrest for an office chair.

Field tests and living labs

The obtain a full understanding of the performance of the materials and their uses, prototypes will be tested in field tests and living lab locations. In the summer of 2023 material samples of the PHBV-rich biomass will be placed in the water of the Marineterrein to test for speed of biodegradability. Later in the project, the leather waste-PHBV composite will be tested in living labs on user acceptance.

A biobased society

Both materials and products are waste-based and biobased, and will hence lower our dependence on fossil resources. Furthermore, these applications will show how to exploit the unique characteristics biobased materials offer, offering an outlook in our future biobased society.

| Duration: |

|

Principal Investigators

Project members

Peter Mooij

TU Delft

Mariet Sauerwein

AMS Institute, TU DelftPartners