Climate change and material scarcity, combined with housing shortages acutely calls for alternative materials that curb the environmental damage of the construction industry. Bio-based materials, and in particular the latest generation of mass timber products can play a vital role in making Amsterdam climate-neutral and circular.

Our experts, Joke Dufourmont and Pablo van der Lugt, dive into the most persisting misconceptions that hamper the large-scale adoption of mass timber construction in this series of articles on ‘Timber construction: facts and fiction’, using examples, data and research results. Let’s kick off with:

Fact or fiction #1: Timber comes from far away and the processing and transportation causes a lot of CO2 emissions. Also, by relying on timber construction, we contribute to deforestation, while we need those forests in our fight to mitigate climate change.

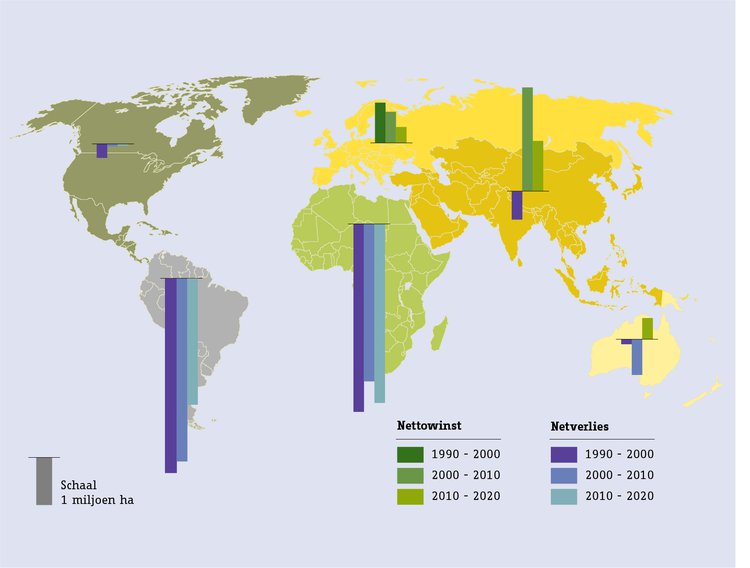

Thanks to sustainable forest management and active planting, the area of forest in Europe has increased over the past 30 years, while in tropical areas deforestation continues - however, the latter not due to increasing demand for wood. ©MaterialDistrict.

Timber construction does not contribute to deforestation

First and foremost, a forest is managed sustainably if no more forest is harvested than is grown, and its health, biodiversity and CO2 storage are maintained or improved. In addition, sustainable forest management must safeguard other ecological functions such as water retention, soil quality, fine dust capture, and respect socioeconomic functions such as worker welfare and the rights of native inhabitants.

Sustainable forest management is ensured in Europe through national forestry legislation of member states, but in many cases even stricter guidelines are met by certifying the entire wood value chain (Chain of Custody) through FSC or PEFC certification. In the Netherlands, this additional certification has been mandatory for (semi) governmental bodies since 2015. As a result, practically all softwood (source for mass timber) and panel material used in the Netherlands is FSC or PEFC certified, and therefore does not contribute to deforestation by definition.

In fact, the wood chain is far ahead in terms of transparency and Corporate Social Responsibility compared to the value chain of traditional materials, thanks to these fully developed Chain of Custody systems.

“Good forestry policy is at the basis of forest conservation, and this can vary greatly from country to country. The largest part of tropical deforestation is caused by conversion to agricultural land.”

Gert-Jan Nabuurs | Professor European forest resources | Wageningen University and Research

“Thanks to sustainable forest management and active planting, the area of forest in Europe has increased over the past 30 years. Furthermore, just about all the mass timber and board material used in the Dutch construction industry is certified and therefore does not contribute to deforestation.”

Pablo van der Lugt | Research Fellow at AMS Institute | Ambassador bio-based building

Preventing tropical deforestation by using more certified (hard) timber

Tropical deforestation is not caused by the timber industry. Tropical deforestation is caused by land conversion for agriculture (e.g. palm oil, soy), livestock farming (e.g. meat industry), infrastructure and – strikingly – mining (e.g. for building materials, especially metals).

In fact, the Netherlands is amongst the biggest contributors to tropical deforestation per capita of Europe, as a consequence of our current system of intensive livestock farming. This industry requires a lot of soy for cattle feed, the demand for which drives tropical deforestation. It follows that growing industrial crops for a bio-based building industry not only yields direct environmental gains, but also indirectly reduces tropical deforestation as a consequence of reduced demand for soy.

It sounds paradoxical, but precisely by using more certified tropical (hard) timber in the Netherlands and hence supporting the business case for sustainable tropical forestry, tropical deforestation is prevented. Note, only 4% of all timber used in the Netherlands comes from tropical areas, of which 65% is PEFC or FSC certified.

Timber fits into a circular building practice

Timber elements requires dry connections and are therefore easy to handle, demountable and fit for reuse. Modular and detachable elements can be “harvested” from existing buildings coming into their end-of-life phase. The loadbearing elements have a long life span and represent the largest volume, and therefore yield the greatest environmental gains when reused.

Timber can already be reused on a large scale while maintaining its quality and structural integrity. The amount of so-called ‘post-consumer’ that is released in this way is expected to increase. This holds especially true for mass timber because of the high economic value that these elements represent; several cross laminated timber (CLT) manufacturers have already set up a take-back system.

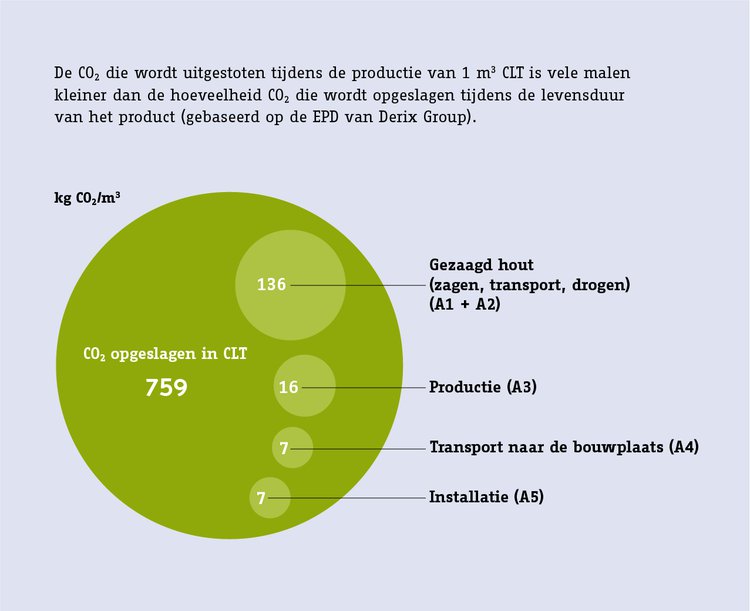

The CO2 emissions from the harvesting, manufacturing and construction processes of CLT, including transportation, energy and glue consumption, are many times smaller than the CO2 stored in the wood. ©MaterialDistrict.

Timber construction is CO2-negative

Last but not least, did you know that sustainable timber construction leads to CO2 reduction in three ways? Firstly, by sequestering CO2 in sustainably managed forests, secondly by storing CO2 in the built environment, and thirdly by avoiding CO2 emissions from traditional construction.

Forests act as CO2 banks. Trees store CO2 by taking it from the atmosphere during the photosynthesis process and converting it into glucose (building block for wood molecules) and oxygen. European forests currently mitigate about 10% of European CO2 emissions annually (435 Mt CO2/year). There's enough potential for this percentage to increase as a result of a growing demand for sustainably grown wood and by planting new sustainably managed forests.

The CO2 that is stored in the trees in the forest, remains captured in timber used in the built environment. Those timber buildings and elements will be around for decades or even centuries (especially through circular construction), and will retain that CO2 for just as long. This way, using timber in construction captures CO2 much longer than would be the case if the wood is burned in biomass power plants. We should hence apply wood in the way that will capture that CO2 for as long as possible.

Thirdly, by building with timber we avoid the emissions that are emitted when making traditional building materials. As a rough rule of thumb, the EU states that if mass timber is used instead of traditional materials, 1.5 tons of CO2 is avoided per ton of timber used (approximately 0.75 tons per m3 of softwood).

On a larger scale, if we would start building with timber on a large scale worldwide, the combined CO2 storage and avoided CO2 could even produce a total CO2 benefit of 110Gt by 2050, almost 14% of the 810 Gt global CO2 reduction required to limit global warming to 1.5 degrees.

“The more often we reuse timber, the longer the CO2 is stored, and the longer the forest can grow back over the life of that used timber. Because timber stores CO2, timber construction allows more and more CO2 to be stored in forests and the built environment and avoids emissions from traditional construction.”

Pablo van der Lugt | Research Fellow at AMS Institute | Ambassador bio-based building

“CO2 is also emitted during the harvesting, manufacture, transport, and construction of timber. However, this is 5 to 10 times lower than the amount of CO2 stored in timber. This is mainly due to the light weight of timber and the short, energy-extensive production process.”

Joke Dufourmont

Former Program Developer Circularity in Urban Regions at AMS Institute

Conclusion: Is building in timber bad for the environment?

Time to conclude. We started this first article of our series with our first 'fact or fiction'. Namely, "timber comes from far away and the processing and transportation causes a lot of CO2 emissions. Also, by relying on timber construction, we contribute to deforestation, while we need those forests in our fight to mitigate climate change". Our experts conclude: fiction.

Ultimately, where the resources required for traditional building materials such as steel and concrete are becoming increasingly scarce, sustainably produced timber makes for an endlessly renewable material, that simultaneously also saves and captures CO2. Using mass timber over abiotic building materials in the built environment therefore contributes to achieving Amsterdam’s ambition to become climate-neutral and circular by 2050.

Stay tuned for the following of the largest misconceptions that our experts dive into:

- There is not enough forest available;

- Timber construction is technically inferior (compared to abiotic materials), and;

- Timber construction is too expensive.

Green Deal Timber Construction

This October, the Metropolitan Region of Amsterdam (MRA) – which includes 32 municipalities, the provinces of North Holland and Flevoland, and Transport Authority Amsterdam (i.e. Vervoerregio Amsterdam) – signed the covenant 'Green Deal Timber Construction in the Metropolitan Region of Amsterdam'. Various private partners and knowledge institutes, including AMS Institute, underlined the set ambitions.

During the signage, we shared a booklet on facts and fiction related to timber construction, created in close collaboration with MaterialDistrict, Pakhuis de Zwijger and the MRA. Download the booklet here (in Dutch) >>

Please note: Although the focus in this article is on residential construction in wood and particularly based on mass timber systems (the term “timber construction” in the text therefore refers to this), the information is largely applicable to other sectors as well, such as non-residential construction and partly to other systems such as timber frame construction.